27 Sep 2023

27 Sep 2023We know that in the past, the winding device of the winding bag machine used to be supported by a thick mandrel and then lined with paper or plastic pipes on the mandrel. When the winding bag did not need support, the support in the winding bag needed to be removed after the winding device was rolled up. Because the connection between the winding bags was very close during the winding operation. So it is very difficult to pull out the support.

Summary of the Invention

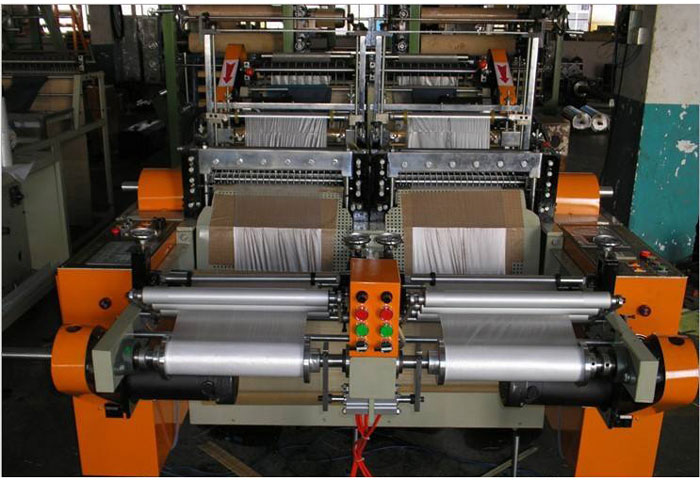

The present invention aims to address the shortcomings of existing technology by providing a coiling bag with a simple structure, supported by a coiling belt. It also includes a coiling device for a bag-making machine that can be easily produced without requiring a supporting coiling bag. The winding device of the rolls connecting bag-making machine is realized through the following technical features:

1. Main Components:

* Metal Rod and Connecting Heads: The bag making machine consists of a metal rod located between two connecting heads. The two ends of the metal rod are connected to the connecting heads.

* Disc-Shaped Connecting Heads: These connecting heads are fixed on bearings at both ends. They are disc-shaped and feature upper, middle, and lower holes, with the middle hole being a threaded hole.

2. Winding Mechanism:

* Dual Metal Rods: Two metal rods are fixed into the upper and lower holes of the connecting heads. These rods enable the winding operation of the coiling bag.

* Removal of Metal Rods: After the winding is complete, the two metal rods are easily removed from the coiling bag due to the gap between the rods.

3. Supporting Fixed Head:

* Fixed Head Design: The invention also includes a fixed head that is elliptical in shape, with a connecting hole in the middle. The fixed head can accommodate different diameters of winding mandrels by offering various hole sizes.

* Connection to the Mandrel: One end of the fixed head connects to the middle hole of the connecting head, and the other end connects to the winding head’s mandrel.

* Mandrel Sleeving: The mandrel is fixed by sleeving its ends on the fixed heads to stabilize the coiling bag during the winding process.

4. Advantages of the Invention:

* Simplified Operation: The structure is simple and easy to operate, making the winding process efficient.

* Support and No Support Options: The device can coil bags both with and without support in the middle.

* Mandrel Conversion: The invention allows for easy conversion of different mandrels by selecting fixed heads with varying hole diameters. This flexibility saves time and costs when replacing devices.

* Improved Work Efficiency: The design enhances production efficiency, reduces labor costs, and facilitates the winding process.

5. General Applicability:

This invention can be easily adapted to different configurations and is applicable across various industries that require bag-making processes. The core principles of the invention remain consistent, and it can be customized to meet specific requirements without altering its fundamental design.

The invention provides a simple, efficient, and cost-effective solution for the coiling process in bag making machines. By streamlining the process, improving operational convenience, and increasing production efficiency, the invention supports both small-scale and large-scale bag production environments.

This winding mechanism offers a significant improvement over traditional methods, addressing both operational challenges and market demands. It provides manufacturers with an enhanced tool to increase productivity, reduce costs, and improve the quality of the final product. The versatility and ease of use make it a valuable addition to modern bag-making production lines.

GET A QUOTE