19 Sep 2024

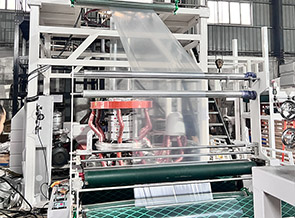

19 Sep 2024Maintenance of Film Blowing Machine includes regular cleaning of equipment, inspection and calibration of heating elements and electrical systems, regular addition of lubricants, timely replacement of worn parts, and maintenance of cooling systems. Keeping detailed maintenance records and training operators will help improve equipment efficiency, extend service life, and ensure stable film quality.

1. Regular cleaning:

After each production, clean the barrel and mold to prevent residual plastic from clogging the equipment. You can use special cleaning agents or hot water to ensure that no old materials remain.

2. Check the heating element:

Regularly check the working status of the heater and check whether the temperature control instrument is accurate to avoid unstable film quality due to uneven temperature.

3. Lubrication system:

Regularly add lubricants to each moving part, especially the reducer and motor bearings, to ensure smooth operation and reduce friction and wear.

4. Check the electrical system:

Regularly check the electrical connections, switches and cables to ensure that there is no wear, short circuit or looseness to prevent electrical failures.

5. Replace worn parts:

Regularly check the wear of the screen, cutter and die head, and replace them in time to ensure the thickness and uniformity of the film.

6. Cooling system maintenance:

Check whether the cooling water circuit is unobstructed, and regularly clean the water pump and cooling pipe to prevent the machine from overheating due to excessive water temperature.

7. Record maintenance:

Maintaining detailed maintenance and maintenance records, including inspection date, content and results, will help to discover and solve potential problems in time.

8. Regular calibration:

Regularly calibrate parameters such as temperature control, pressure and stretch ratio to ensure accuracy and consistency during the production process.

9. Operator training:

Regularly train operators to improve their understanding and maintenance capabilities of the equipment and ensure safe and effective operation.

GET A QUOTE