Description:

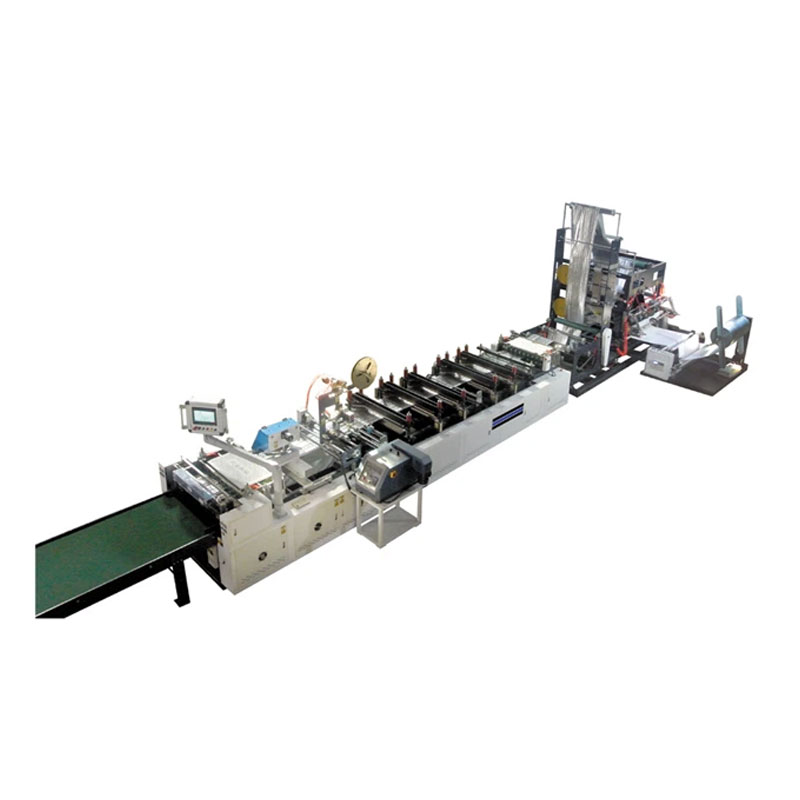

Air Bubble Envelop Box Bag Making Machine, The outside of the envelope is aluminum foil ,inside is bubble film. Machine speed can reach 20-50 pcs/min; highout; stable perforance; securiet and relability.

Application:

Aluminum laminated bubble film insulation guested bags are widely used in electronic appliances, instrumentation, hardware lighting, handicrafts, computers, audio, industrial control chassis, glass, ceramics, etc., laminated bubble can also be used for elastic lining of handbags, industrial production of sound insulation, Insulation materials, agricultural insulation materials, floating equipment for aquaculture, protective mats for sporting goods, life-saving equipment for water operations, floor decoration and cushioning for families and hotels.

Features:

Aluminum laminated Air Bubble Envelop Box Bag Making Machine performance and characteristics:

1. Aluminum laminated bubble film insulation bag making machine adopts PLC touch display, can be programmed computer program.

2. Automatic counting, you can set the number of any bag, time to stop the machine.

3. Arbitrary fixed length, color code tracking and positioning

4. Automatic correction of paper discharge

5. composite bubble film bag making machine comes with folding and gluing functions

Technical Parameters:

|

Applied Raw Material

|

Aluminized Air bubble , Kraft Paper Air bubble, Pearlescent Air bubble, PE Foam Film, and so on.(thickness more than 90gsm is best)

|

|

Speed

|

10-40M/min( depends on bag size)

|

|

Max. Bag width

|

600mm

|

|

Max. Bag length(height)

|

700mm(include the self-adhesive part)

|

|

Max. Unwinding Diameter

|

1400mm

|

|

Max. Unwinding Width

|

1600mm

|

|

Machine Weight

|

4200KG

|

|

Machine Size

|

18000*2500*2000mm(L*W*H)

|

|

Total Power

|

16KW

|

|

Power Supply

|

3Phases, 4Lines, 380V, 50Hz

|

|

Air Supply

|

5-10kg/cm2

|

D: Supporting Facility:

1. Power Supply: 3phases, 4line,380V, 50hz, with ground wire (Ground wire requirement: Using a diameter 30-50mm, length 1.5m steel bar directly into the ground, lead wire on the upper use 0.6-0.8mm2 wire), absolutely forbidden to connect the ground wire on the machine.

2. Installation Site: The ground hardenss is required to ensure that after the completion of equipment installation and debugging, in the process of operation, there will be no abnormal operation of equipment or damage to equipment, such as foundation settlement.

3. Air Supply: 5~10kg/cm²

4. Total Power: 16KW

Benefits

1.The Air Bubble Envelop Box Bag Making Machine is its ability to integrate air bubble cushioning with a box-like envelope, offering both cushioning and structural support.

2.Full automation streamlines the production process, reducing labor costs and ensuring consistent bag quality.

3.Versatility: The machine can accommodate various bag sizes, materials, and designs, catering to different packaging needs.

4.Air bubble envelop box bags provide both cushioning and impact resistance, minimizing the risk of damage during transportation.

5.Proper machine setup, regular maintenance, and operator training are essential to ensure the reliable and consistent production of high-quality air bubble envelop box bags. An air bubble envelop box bag making machine offers businesses a comprehensive and efficient solution for packaging fragile items securely and conveniently.