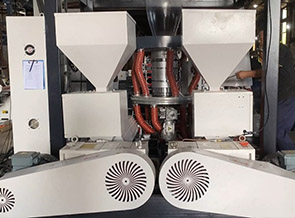

An High Speed ABA Die PE Film Making Machine is a specialized equipment configuration used in the plastics industry to produce plastic films using the A-B-A co-extrusion process. This process involves three layers of plastic material, with the outer layers (A) and an inner layer (B) providing unique properties and functionalities. The ABA die configuration allows for enhanced film properties and versatility. It is the ABA Three-layer Co-extrusion Blown Film Extruder, which is to make three layers coextrusion film.

The type of the film: ABA, inner layer and outside layer with same material and the middle with another kind of material.

Raw material: PE, including LDPE, LLDPE, HDPE, etc.

Meanwhile, the internal filling layer can be added recycled material and calcium carbonate, whose proportion can be 50% of total. The raw material cost in the process of production can be greatly reduced to provide clients with a strong market competitiveness.

Co-Extrusion Capability:

The ABA die configuration enables the simultaneous extrusion of three layers of plastic materials. This can include different types of resins or additives in the layers to achieve specific properties, such as barrier properties, strength, flexibility, or color.

Layer Thickness Control:

The High Speed ABA Die PE Film Making Machine allows for precise control of the thickness of each layer, contributing to the overall performance and characteristics of the final film.

Enhanced Properties:

By combining different types of plastics or additives, the ABA co-extrusion process can result in films with improved mechanical properties, barrier properties, optical clarity, and more.

Versatility:

The ability to create multi-layer films with distinct properties makes the ABA die plastic film making machine suitable for various applications.

Possible Products

HDPE & LDPE & BIODEGRADABLE FILM ROLLS