Products Description:

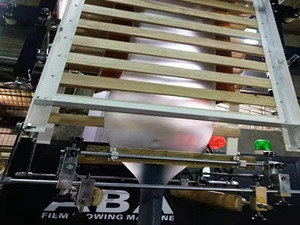

The ABA Mini PE Film Blowing Machine is a specialized piece of equipment used in the plastics industry to produce plastic films through a blown film extrusion process. It is designed for smaller-scale production and is often used to create plastic films for various applications, such as packaging materials, bags, wraps, and more. The "ABA" in the name refers to the co-extrusion process involving three layers: A-B-A, where "A" represents the outer layers and "B" represents the inner layer. This co-extrusion setup allows for enhanced film properties and versatility.

Technical Parameters:

| Model |

MNABA-600 |

MNABA-800 |

| Screw Diameter |

45mm×2 |

50mm×2 |

| Screw Ratio |

L/D30:1 |

L/D30:1 |

| Screw Speed |

10-100r/min |

10-100r/min |

| Power of Main Motor |

11kw×2 |

15kw×2 |

| Max. Extrusion Output |

40-80kg/h |

50-100kg/h |

| Max. Folding Width of Film |

600mm |

800mm |

| Thickness of Film |

0.008-0.10mm |

0.008-0.10mm |

| TotalPower |

55kw |

68kw |

| Weiaht of Machine |

2500kg |

3000kg |

| Overall Dimension(LxWxH) |

3.0×1.8×3.9m |

3.2×2.0×4.2m |

Features:

1.Compact Size: The ABA Mini PE Film Blowing Machine is smaller in size compared to larger industrial machines, making it suitable for limited workspace and smaller production volumes.

2.Co-Extrusion Capability: The ABA configuration enables the machine to create films with three layers, each potentially having different properties. This enhances the overall film performance, such as strength, barrier properties, and aesthetics.

3.Plastic Resins: The machine can process a variety of plastic resins, including LDPE (low-density polyethylene), LLDPE (linear low-density polyethylene), HDPE (high-density polyethylene), and more, depending on the desired film characteristics.

4.Control and Automation: Many modern ABA mini film blowing machines come equipped with advanced controls and automation features, allowing for precise adjustments of parameters like temperature, air pressure, and extrusion rates.

Modular Accessories:

Barrel and screw , Ceramic Heater with three zone cooling

ABA there layers die head with double lips air ring

Traction Unit Lift System

Single Position Friction Rewinder