Products Description:

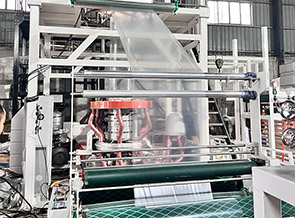

Double winder three layer film blowing is a new product developed by our company according to the needs of the market. It absorbs the advanced technology of similar products at home and abroad, which is suitable for all kinds of high-grade film packaging. The film produced by the double winder three layer film blowing can be widely used for light and heavy packaging because of its good barrier property, preservation, moisture resistance, frost resistance, oxygen barrier and oil resistance.

Technical Parameters:

|

Model

|

SJ-45x3/FM1000

|

SJ-50x3/FM1200

|

SJ-55x3/FM1500

|

SJ-60x3/FM2000

|

SJ-65x3/FM2500

|

|

Screw Diameter

|

45mm

|

50mm

|

55mm

|

60mm

|

65mm

|

|

Screw Ratio

|

L/D30:1

|

L/D30:1

|

L/D30:1

|

L/D30:1

|

L/D30:1

|

|

Screw Speed

|

15-120r/min

|

15-120r/min

|

15-120r/min

|

15-120r/min

|

15-120r/min

|

|

Power of Main Motor

|

11kwx3

|

15kwx3

|

18.5kwx3

|

22kwx3

|

30kwx3

|

|

Range of Die

|

¢200mm

|

¢250

|

¢300

|

¢500

|

¢600

|

|

Output

|

100kg/h

|

120kg/h

|

150kg/h

|

180kg/h

|

200kg/h

|

|

Thickness of Film

|

0.01-0.10mm

|

0.01-0.10mm

|

0.01-0.10mm

|

0.03-0.10mm

|

0.03-0.10mm

|

|

Max. Folding Width

|

1000mm

|

1200mm

|

1500mm

|

2000mm

|

2500mm

|

|

Electric Total Capacity

|

76kw

|

88kw

|

102kw

|

130kw

|

156kw

|

|

Weight of Machine

|

4200kg

|

5300kg

|

6200kg

|

8600kg

|

10600kg

|

|

Overall Dimension

|

6600x4100x5000mm

|

6800x4300x6000mm

|

7000x4800x6800mm

|

7800x5300x8600mm

|

8600x6200x9600mm

|

Features:

* The three-layer co-extruded composite film can extend the shelf life of liquid packaging.

* The barrel and screw of the extruder are made of high-quality alloy steel through precision machining and nitriding treatment to achieve the best hardness and durability.

* The auxiliary machine is equipped with a platform type worktable, which makes the operation convenient and prepares the bubble ring.

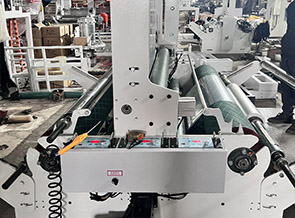

* Coiling device: Double-receiving and double-section, its power adopts torque motor, which can maintain proper tension, and the winding is neat and easy to change.

Application:

* Double winder three layer film blowing is suitable for blowing plastic composite films such asLDPE, HDPE and LLDPE.

* Widely used in express bags, liquid packaging, printing substrates, export product packaging, industrial packaging.