Description:

The automatic punching bag making machine uses the materials such as LDPE and HDPE film to make vest bags. It is equipped with PLC, servo (stepping) motor to fix the length, photocell, auto-puncher, and auto-conveyor, which has high production efficiency.

An automatic punching bag making machine is specialized equipment designed to automate the process of producing various types of bags through punching or die-cutting techniques. These machines are commonly used in the packaging industry to create bags with specific shapes, holes, or perforations.

Features:

1.The machine is equipped with a system to feed various types of flexible materials, such as plastic films, paper, fabric, or non-woven materials.

2.The key feature of the machine is the punching mechanism, which uses specially designed dies to cut out specific shapes, holes, or perforations in the material. The punches can be customized to create various bag designs and features.

3.Automatic punching bag making machines often feature a quick and easy die-changing system, allowing operators to switch between different punch designs efficiently.

4.To ensure accurate punching and consistent results, the machine may have material tension control systems that maintain proper tension on the material being punched.

Applications:

1.Automatic punching bag making machines are used to create bags with handles, whether they are T-shirt style bags, loop-handle bags, or other handle designs.

2.These machines are employed to produce bags with customized shapes and perforations for retail packaging, making them visually appealing and functional for displaying products.

3.Bags with punched holes or handles are suitable for hanging on display hooks, making them ideal for retail environments.

4.Bags with unique shapes or perforations can enhance the presentation of products, creating visual interest and attracting consumer attention.

Technical Parameters:

| Model |

GFQ-600 |

GFQ-700 |

GFQ-800 |

| Bag Width |

160-260mm×2 |

160-300mm×2 |

160-350mm×2 |

| Bag Length |

240-600mm |

240-600mm |

240-600mm |

| Bag Thickness |

0.015-0.035mm |

0.015-0.035mm |

0.015-0.035mm |

| Speed |

60-120pcs/min×4 |

60-120pcs/min×4 |

60-120pcs/min×4 |

| Air Pressure |

5kg/cm² |

5kg/cm² |

5kg/cm² |

| Total Power |

7kw |

8kw |

9kw |

| Weight of Machine |

1300kg |

1400kg |

1500kg |

| Overall Dimension (L×W×H) |

5.3×1.2×1.8m |

5.3×1.3×1.8m |

5.3×1.5×1.8m |

Optional Equipment:

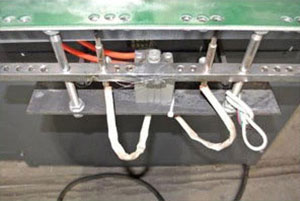

1.Automatic punching part

2.Hydraulic swing arm manual puncher