Description:

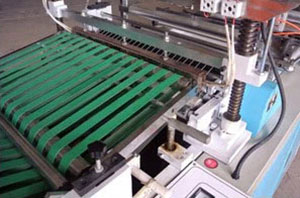

BOPP side sealing bag making machine is suitable for hot cutting and bag making of printed and non-printed plastic films such as BOPP, OPP, PE.

BOPP side sealing bag making machine has the advantages of reasonable design structure, convenient operation and high degree of automation, and can be used for producing various composite materials for bag making, and is an ideal bag making device for producing middle sealing bags, side sealing bags and four side sealing bags.

Features:

* The whole BOPP side sealing bag making machine adopts microcomputer control and stepping motor traction material (servable motor control system can be configured).

* The length of the random fixed-length photo power tracking is accurate and stable or the target tag is lost, the machine will automatically stop.

* With double-sided tape, it can automatically work in stepping and counting, and can also automatically set the counting alarm.

* Lace heat seal, the same temperature adjustment automatically makes the final package firm and flat.

* All parameters are displayed in real time by the man-machine interface, and the bag making speed, bag length, temperature, counting, finished product delivery, etc. can be preset.

* LPC automatic deviation correction, dual photoelectric tracking and discharging, automatic constant tension control AC frequency conversion constant speed automatic feeding.

* Pneumatic multi-function automatic punching, automatic removal of edge material removal, with static elimination device.

Technical Parameters:

| Model |

DRW-600 |

DRW-700 |

DRW-800 |

DRW-900 |

DRW-1000 |

| Bag Width |

10-550mm |

10-650mm |

10-750mm |

10-850mm |

10-950mm |

| Bag Length |

50-800mm |

50-800mm |

50-800mm |

50-800mm |

50-800mm |

| Bag Thickness |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm |

| Bag Speed |

40-180pcs/min |

40-180pcs/min |

40-180pcs/min |

40-120pcs/min |

40-120pcs/min |

| Total Power |

3kw |

3.6kw |

3.8kw |

4.5kw |

4.7kw |

| Machine Weight |

800kg |

900kg |

1000kg |

1100kg |

1200kg |

| Overall Dimension (L×W×H) |

3.3×1.0×1.7 |

3.3×1.1×1.7 |

3.3×1.2×1.7 |

3.3×1.3×1.7 |

3.3×1.4×1.7 |