Description:

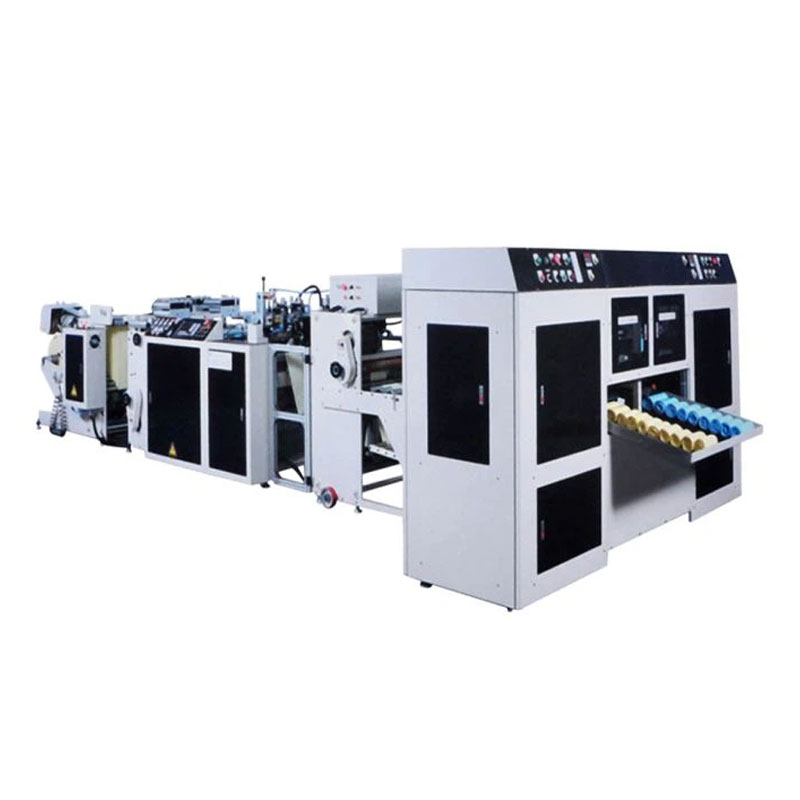

The coreless rolling bag making machine has been designed and manufactured by professional staff and experienced designers. It is a model that uses computer control and material to pull the motor. This coreless rolling bag making machine adopts microcomputer computer control, stepper motor dragging can be equipped with servo motor control system and stepper photoelectric tracking.

Coreless rolling bag making machine is also equipped with functions such as photoelectric tracking, microcomputer length setting, automatic counting, and automatic alarm. It is ideal for making high and low pressure vest bags, flat pockets, sanitary napkin bags, and break-to-roll garbage bags. Can be made into a paperless roll bag.

Features:

* The tension-free technology is used to seal the tissue, synchronous sealing and cutting, and the base film is beautiful.

* Adopts the process of continuous tape-type bag making, continuous roll flat bag and flat bag function.

* Computer automatic control, automatic counting and settable counting alarm, high efficiency, saving manpower and time.

* The heat sealing cold cutting device is adopted, and the intelligent temperature control system makes the bag sealing firm and flat.

* The host adopts the inverter to control the speed regulation; the winding is controlled by POC; the discharging is controlled by the inverter.

Applications:

1.Coreless rolling bags are commonly used as trash liners for waste bins and containers, offering a convenient and hygienic way to dispose of trash.

2.These bags can be used for packaging various items, including textiles, garments, food products, and more.

3.Coreless rolling bags are suitable for storing and organizing small items, making them useful for household and organizational purposes.

4.These bags find applications in industrial settings, such as manufacturing and production, where temporary storage or containment is needed.

Technical Parameters:

| Product Name |

Coreless rolling bag making machine |

|

Model

|

XYWX-450*2

|

|

Bag width

|

100-250mm

|

|

Bag length

|

200-1500mm

|

|

Bag thickness

|

0.008-0.035mm

|

|

SpeeF

|

100m/min

|

|

Unwinding material diameter

|

Φ900mm

|

|

End product diameter

|

Φ150mm

|

|

Air compressor

|

6hp

|

|

Total power

|

12.5kw

|

|

Machine weight

|

3350kg

|

|

Overall dimension

|

7500*1750*1700mm

|