Description:

The Multi-function Bag Making Machines takes the main materials like HDPE, LLDPE and LDPE to manufacture shopping bags which are widely used for packing clothing, shoes, documents and so on.

The machine adopts microcomputer PLC control, the liquid crystal touch screen actual display and aservomotor to fix the length,photoelectric tracking and automaticair pressure to punching holes synchronously.

Product advantages:

1.The length and width of the bag can be adjusted during production, so this equipment allows you to produce bag of various specifications.

2.The production speed of bag is very fast. Because the equipment is highly automated and the stability during production is very good, it can greatly improve the production efficiency of the bag;

3.Easy to operate and easy to maintain. This machine uses a PLC control system, so it is easy to operate. In addition, the quality of this machine is very good, so it does not need to spend a lot of effort in maintenance.

Applications:

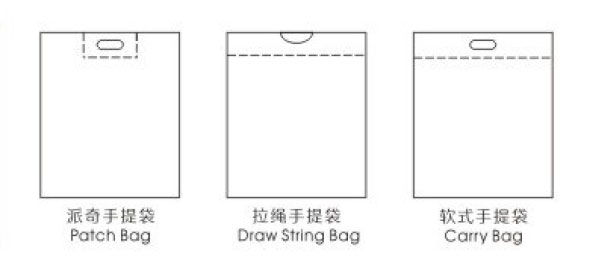

1.Multi-function bag making machines can produce bags for retail packaging, such as shopping bags, T-shirt bags, handle bags, and more.

2.These machines are ideal for producing bags used in supermarkets, convenience stores, and other retail outlets.

3.Multi-function bag making machines can manufacture bags for food packaging, including pouches, stand-up bags, resealable bags, and heat-sealed bags.

Technical Parameters:

|

Model

|

RXYQ-800

|

RXYQ-1000

|

|

Bag Size: Width

|

250-500mm

|

250-650mm

|

|

Bag Size: Length

|

250-650mm

|

250-850mm

|

|

Production speed

|

Patch 60cyce/min,Carry 65cyce/min

|

Patch 60cyce/min,Carry 65cyce/min

|

|

Thickness of film

|

0.045-0.09mm

|

0.045-0.09mm

|

|

Total Power

|

8kw

|

9.5kw

|

|

Weight of Machine

|

2800kg

|

3400kg

|

|

Overall Dimensions

|

6500×2000×1750mm

|

6500×2200×1750mm

|

Notice: Air compressor is not included.