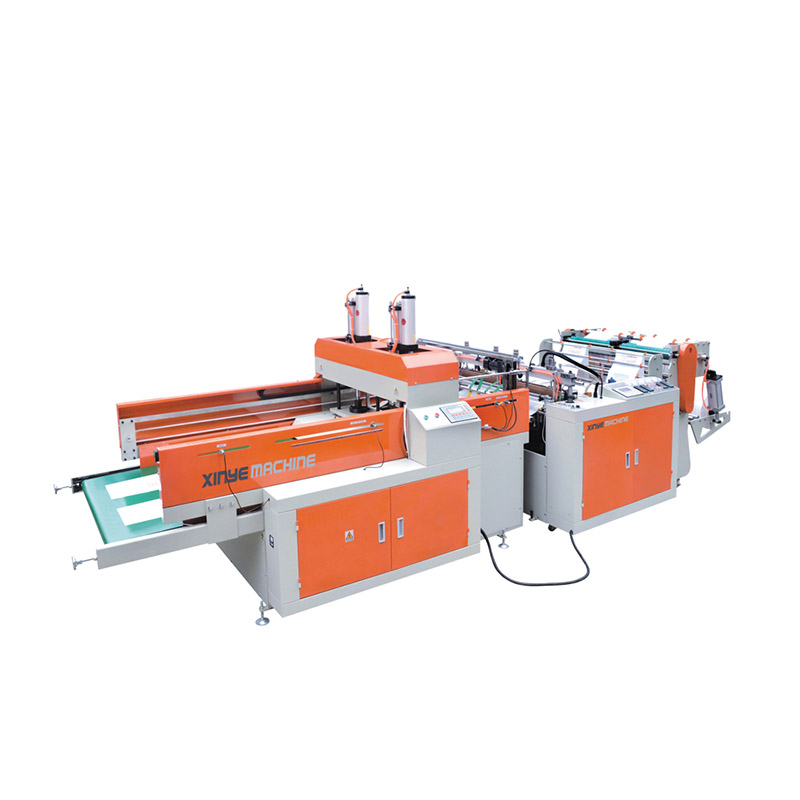

Compared with similar equipment, PLC control vest bag making machine has the advantages of more compact structure, higher output, better product quality, more energy-saving machine and easier operation. It can be widely used in the production of high-transparency packaging film to create considerable economic benefits.

In order to meet customers' requirements for high quality and high production bag making equipment, PLC control vest bag making machine adopts extruder with forced feeding function, precision ceramic heater, precision double air ring, horizontal rotary traction system and IBC.

In addition, it adopts advanced technology and equipment such as cold system, fully automatic double-section and double-receiving surface friction winder, computer centralized control system.

Precision

Tracked by 2 photocells for very accurate printing.

Automation

Adopt PLC control, double step (servo) motor fixed length and LCD touch screen actual display.

Integration

Complete feeding, sealing, cutting, punching and transportation at one time, saving manpower and economy.

Versatility

Suitable for use in HDPE, LDPE film production and printing of two-color or colorless vest bags.