Description:

A PVC shrink bag making machine is specialized equipment designed for the production of PVC (Polyvinyl Chloride) shrink bags. PVC shrink bags are commonly used for packaging and protecting various products, providing a tight and secure wrap that conforms to the shape of the item when heat is applied. These bags are widely used in industries such as food packaging, cosmetics, electronics, and more.

This PVC shrink bag making machine can make PE (LDPE/HDPE) arc-shaped bags and PVC shrink film bag for other usage. It adopts step motor, micro-computer and the digital controller to change bag length easily, save labor, and material. The waste material can be sliced automatically. It ensures the bag quality and improves competitiveness. The uncolored bags can be made in double lines. It is equipped with the device which can collect and send the end products in stack. It is equipped with photocell to track the printed bag.

1. With step motor and numerical computer controlling, the length of bags can be easily set;

2. Edge waster can be lowered down automatically and its length can be easily set in the computer:

3. Photo-eye is used to track printed bags;

4. There are also double line models for your choice.

Technical Parameters:

|

Single Line Model

|

PVC PE-400

|

PVC PE-500

|

PVC PE-600

|

PVC PE-700

|

|

Max Width

|

50-350mm

|

50-450mm

|

50-550mm

|

50-650mm

|

|

Max Length

|

100-450mm

|

100-450mm

|

100-650mm

|

100-700mm

|

|

Error in Length

|

±0.5-1mm

|

±0.5-1mm

|

±0.5-1mm

|

±0.5-1mm

|

|

Speed per Minute

|

15-120pcs/min

|

15-120pcs/min

|

15-120pcs/min

|

15-120pcs/min

|

|

Width of Silica gel Board

|

100*350mm

|

100*450mm

|

100*550mm

|

100*650mm

|

|

Total Power

|

2.5kw

|

3kw

|

3.5kw

|

4kw

|

|

Weight of Machine

|

700kg

|

800kg

|

900kg

|

1000kg

|

|

Overall Dimensions

|

3300*850*1300mm

|

3300*950*1300mm

|

3300*1050mm*1300mm

|

3300*1150*1300mm

|

|

Double Line Model

|

PVC PE-500

|

PVC PE-600

|

PVC PE-700

|

|

Max Width

|

50-200mm*2

|

50-220mm*2

|

50-300mm*2

|

|

Max Length

|

100-450mm

|

100-650mm

|

100-700mm

|

|

Deviation in Length

|

±0.5-1mm

|

±0.5-1mm

|

±0.5-1mm

|

|

Bag Making Speed

|

15-120pcs/min*2

|

15-120pcs/min*2

|

15-120pcs/min*2

|

|

Width of Silica Gel Plate

|

100*450mm

|

100*550mm

|

100*650mm

|

|

Total Power

|

3.5kw

|

4kw

|

4.5kw

|

|

Weight of Machine

|

850kg

|

950kg

|

1050kg

|

|

Overall Dimensions

|

3300*950*1300mm

|

3300*1050mm*1300mm

|

3300*1150*1300mm

|

Features:

1.The PVC shrink bag making machine is equipped with a system to handle PVC shrink film rolls. The film is unwound and fed through the machine for bag production.

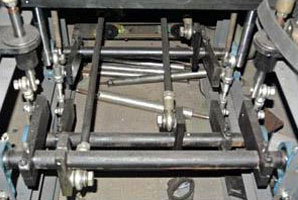

2.The machine's key feature is the sealing and cutting mechanism. It seals and cuts the PVC shrink film into the desired bag size and shape.

3.PVC shrink bags are created by applying heat, which causes the film to shrink tightly around the product. The machine may include a heat tunnel or chamber for this purpose.

4.Operators can adjust settings for bag dimensions, cutting length, sealing parameters, and heat application to create customized PVC shrink bags.

5.A control panel allows operators to monitor and control the machine's operations, ensuring accurate bag production.